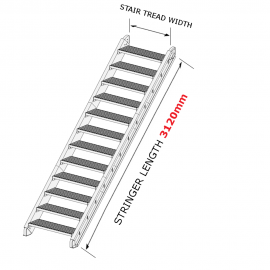

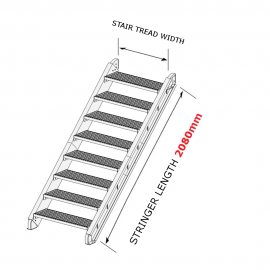

Galvanized steel staircase for a total rise of 2,6 to 4,5 meters

1131,68 € – 2495,05 € excl. VAT

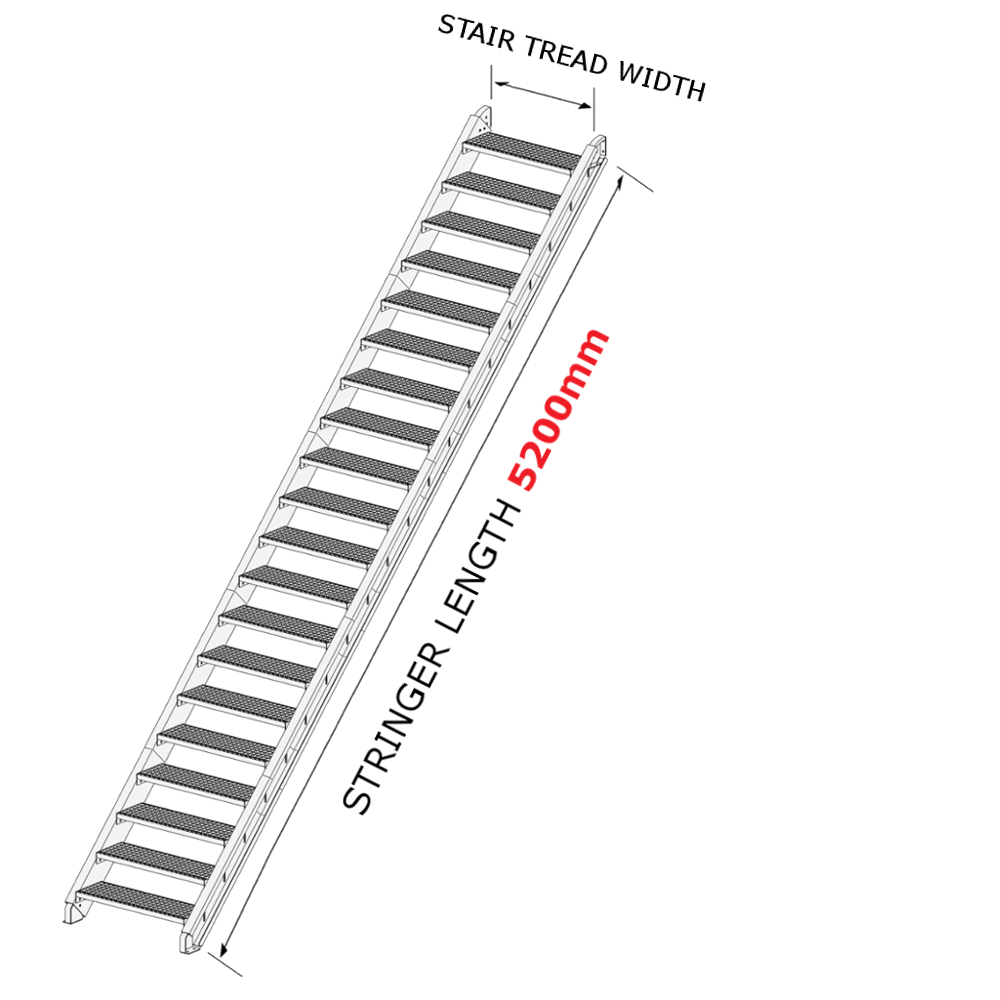

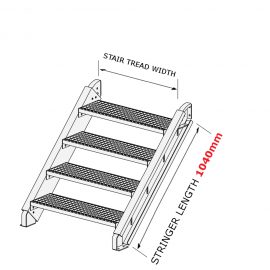

Complete kit for a straight industrial staircase 5200mm, including 2 pedestals, 2 arc fittings, 10 modular stair stringers of 1040mm, 8 connector pieces, 80 pieces of galvanized bots and nuts and 20 stair treads.

- Excellent service (customers rate us an average of 4.5/5)

- Everything in stock with more than 6000 m² of stock

- Inexpensive shipping

- Fast delivery

Galvanized steel staircase for a total rise of 2,6 to 4,5 meters

This kit contains everything you need for your basic galvanized industrial staircase:

– 10 galvanized modular stringers with a length of 1040mm (left + right)

– 8 modular connector pieces

– 20 galvanised steel stair treads, choice of width

– 80 M12 galvanized bolts and nuts

– 2 galvanized stair pedestals (left + right)

– 2 galvanized arc fittings

– 8 anchor bolts

All parts of these steel stairs are galvanized and suitable for both indoor and outdoor use.

The total width of your staircase is the width of your chosen stair tread plus 2 x 50mm, which is the width of the stringer.

The package with 1040 mm stringers is suitable for total rise of 2,6 meters (with the staircase at an angle of 60°) to 4,5 meters (with the staircase at an angle of 30°). Both extremes are possible – due to the slotted holes the stair treads can be adjusted to be perpendicular. For an ideal staircase we recommend to get as close as possible to an angle of 45°.

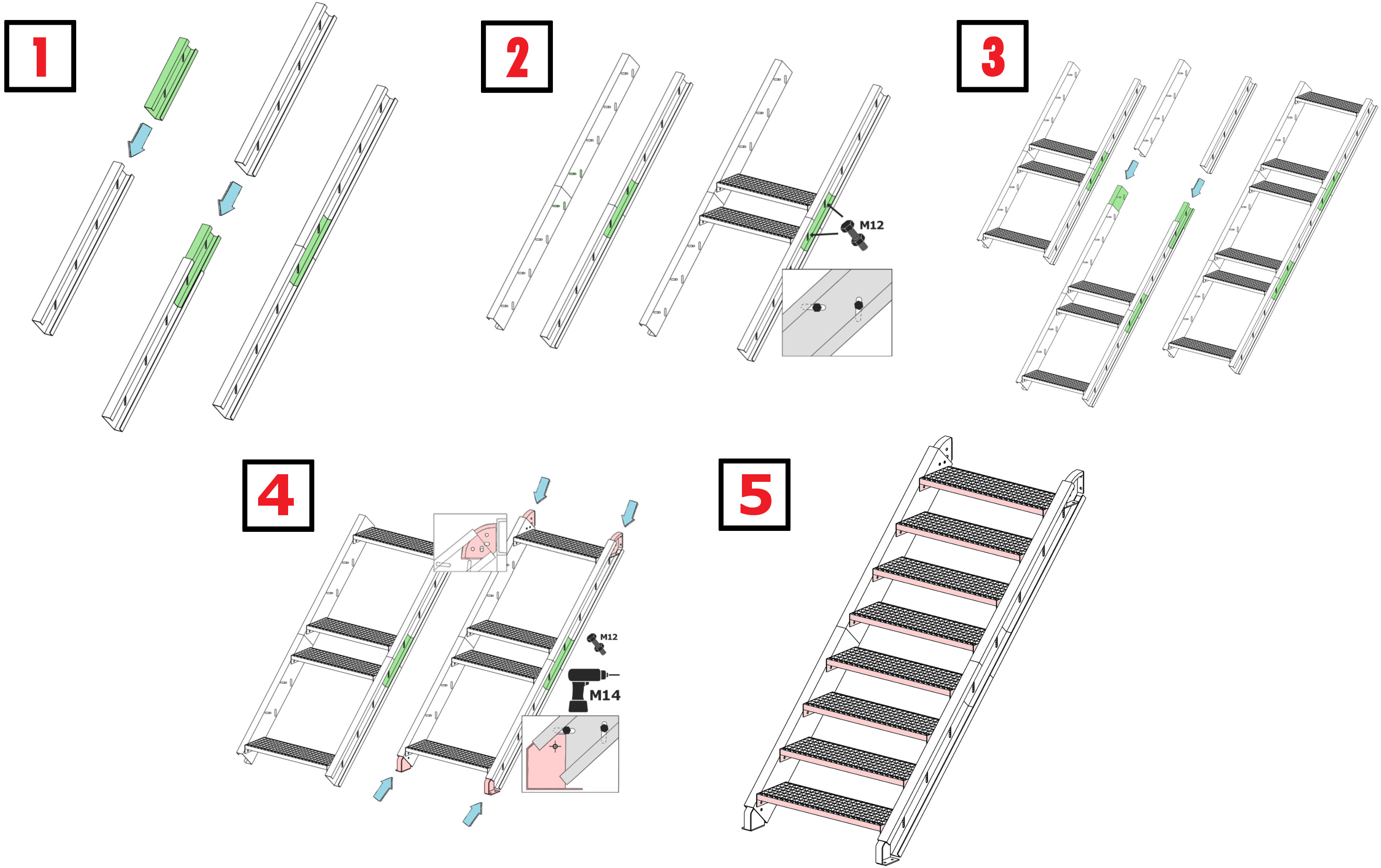

Easy to assemble

Our galvanized stairs are deceptively easy to assemble and install, so you save often expensive installation costs for not only the stairs but the handrail.

|

Attach the stringers using the connector pieces, slide the left connector into the left side stringers and the right connector into the right side stringers and make sure the perforations match up. |

|

Make sure the stringers are properly aligned before attaching the stairs. Where the stringers are connected by the modular connector piece , fasten two treads between the stringers using bolt + nut m12. Do not fasten the treads too tighly in order to facilitate the addition of the other treads, but enough to make everything solid. In the illustration, we initially attach only the treads on the connector pieces to make it less heavy, but if you have enough (mechanical) assistance you can secure all the treads straight away. |

|

Depending on the required length of the staircase, attach additional modular segments to reach your total length. |

|

Attach the two arc fittings to the upper floor. The recommended bore diameter is about 12 mm. Drill and fasten the first fitting, taking into account that the space between the arc fittings depends on the width of your chosen treads. Measure the distance between the inside of the stringers to determine the position of the second arc fitting. Slide the stringers over the arc fittings. Depending on the weight of your stairs, it is wise to have some the help or use a forklift for example. Then make sure the upper tread is perpendicular and attach it by drilling and fixing with a bolt and a nut. Attach the left and right pedestals at the bottom of the stairs. Drill through the indicated holes and fasten with a bolt and nut. You can optionally fix the pedestals to the ground by using the provided anchor bolts. |

|

Now fasten the rest of the treads between the stringers as described in point 2. Consider the angle of the steps so that they are perfectly perpendicular. You can adapt the angle using the slots on the stringers. If the treads become difficult to place and fasten, you can loosen the previous step to move the stringers slightly further apart. |

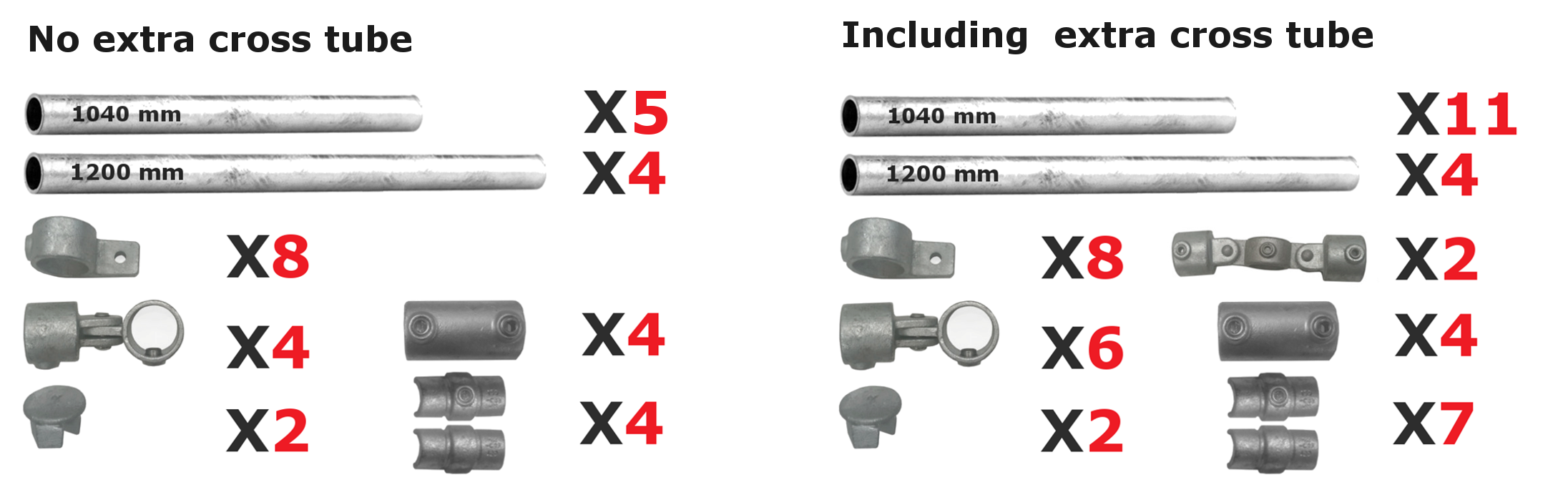

Modular handrail in galvanized tube.

The handrail consists of a robust galvanized tube Ø 42.2, which is supplied at the length of your stair stringers – so 1040mm. There are 2 vertical tubes with 1200mm. The necessary nuts / bolts / M10 and tube clamps are provided, according to your choice:

If you pick the extra cross tube option, we supply a galvanized tube Ø 42.2 measuring 1040mm as it is variable what size you need depending on the angle of your staircase. This way you have an an excess size you can cut to size to fit your spacing. The sawing is easy to do with a regular metal saw. The tube clamps can be tightened with an Allen key.

The handrail can be fixed by drilling holes on the stairway stringer at the desired location, the bolts and nuts M10 are provided. The clamps can rotate freely before fastening, so your railing can easily be adjusted to the angle of your staircase.

Related products

-

DIY staircase kits

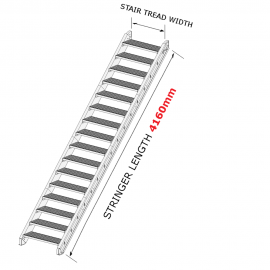

Galvanized steel staircase for a total rise of 2 to 3,6 meters

905,52 € – 2216,70 € excl. VAT Select options This product has multiple variants. The options may be chosen on the product page -

DIY staircase kits

Galvanized steel staircase for a total rise of 1,5 to 2,7 meters

662,85 € – 1723,53 € excl. VAT Select options This product has multiple variants. The options may be chosen on the product page -

DIY staircase kits

Galvanized steel staircase for a total rise of 1 to 1,8 meters

453,19 € – 1136,24 € excl. VAT Select options This product has multiple variants. The options may be chosen on the product page -

DIY staircase kits

Galvanized steel staircase for a total rise of 0,5 to 0,9 meters

227,03 € – 623,87 € excl. VAT Select options This product has multiple variants. The options may be chosen on the product page -

DIY staircase kits

Spiral staircase – Civik Zink – DIY kit

1020,60 € – 1231,60 € excl. VAT Select options This product has multiple variants. The options may be chosen on the product page